HRC45 2 Flute Carbide Ball Nose End Mill Cutter

Using sub-fine grain tungsten carbide steel as base material, these carbide end mills has high hardness and excellent wear resistance. Enhanced by the latest coating, our solid carbide end mills is suitable for steel, mould steel, cast iron materials. Square carbide end mill, corner radius end mill and ball nose end mill for your choose.

| Raw Material | 100%Virgin Material Carbide Rods |

| Cnc Machine | Germany And Australia Machine |

| Carbide Rods | hrc45 is YG10X,hrc55 is YL10.2,hrc65 is Japan Carbide Rods |

| Coating | hrc45 is ALTin,hrc55 is Tisin,hrc65 is Blue Nano Coating |

| Coating Color | hrc45 is ALTin,hrc55 is Tisin,hrc65 is Blue Nano Coating |

HRC45 Carbide End Mill |

Mill Dia | LOC | Shank Dia | OAL |

1 | 3 | 4 | 50 |

1.5 | 4.5 | 4 | 50 |

2 | 6 | 4 | 50 |

4 | 10 | 4 | 50 |

4 | 16 | 4 | 75 |

4 | 20 | 4 | 100 |

5 | 13 | 5 | 50 |

6 | 15 | 6 | 50 |

6 | 25 | 6 | 75 |

6 | 30 | 6 | 100 |

6 | 40 | 6 | 150 |

8 | 20 | 8 | 60 |

8 | 25 | 8 | 75 |

8 | 35 | 8 | 100 |

8 | 40 | 8 | 150 |

10 | 25 | 10 | 75 |

10 | 40 | 10 | 100 |

10 | 50 | 10 | 150 |

12 | 30 | 12 | 75 |

12 | 45 | 12 | 100 |

14 | 40 | 14 | 100 |

14 | 60 | 14 | 150 |

16 | 45 | 16 | 100 |

16 | 70 | 16 | 150 |

18 | 45 | 18 | 100 |

18 | 70 | 18 | 150 |

20 | 45 | 20 | 100 |

20 | 70 | 20 | 150 |

Tips: The above specifications are standard Size, with a large amount of stock. At the same time, we support OEM customized production, the diameter is 0.2mm to 25mm, the Total length is 50mm to 200mm, include inch size end mill , the number of Flute is 4F, 5F, 6F, 8F and the logo could be customized.

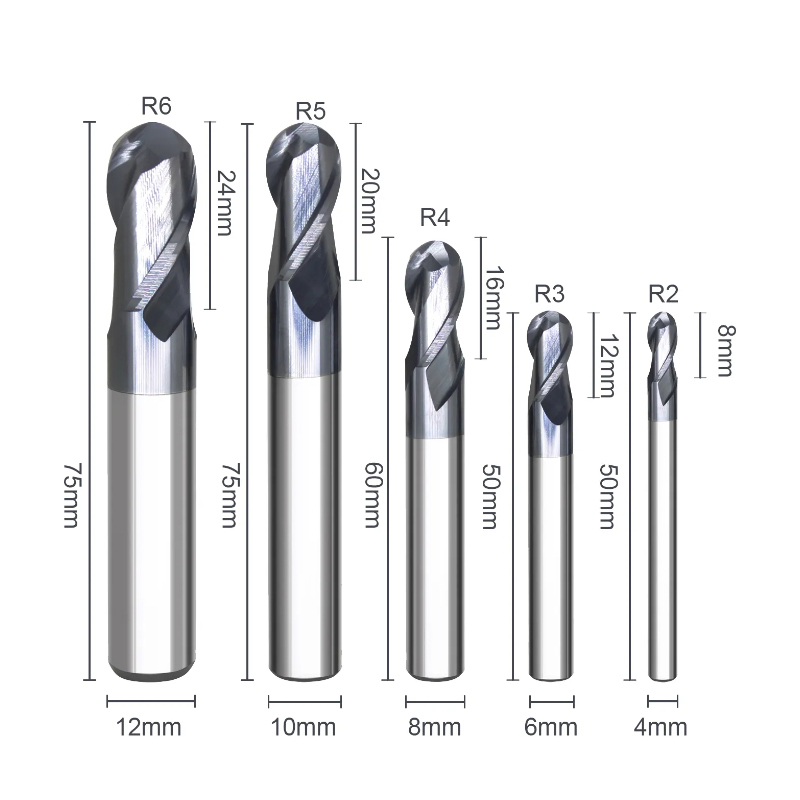

2 Flute Solid Carbide Ball Nose End Mill, Coating

HRC: HRC45 HRC55 HRC58 HRC60 HRC65

Coated: AlTiN, TiAlN, TiSiN, TiN, DLC,Nano, Diamond

1.Widely used in the processing of high-hardness materials, such as copper, cast iron, carbon steel, and mould steel etc.

2.Recommend to select the size with minimum overhang required as long overhang is vulnerable to vibration, and thus need to reduce RPM and the feed volume

3.Need to adjust RPM and feed rate reasonably accoring to cutting depth, the machine rigidity and other conditions of usage

4.With highly heat-resistant ALTIN coating, can be used for high-speed processing

5.High toughness, using grain-sized carbon tungsten as the raw material

6.Help to increase the smoothness, reduce the friction coefficient,and improve the lathe efficiency, thus save more production time